+8613776545860

In today’s construction industry, durability, strength, and corrosion resistance are more important than ever. At Chemlead New Material, we operate a state-of-the-art fiberglass rebar (FRP rebar) factory dedicated to producing high-quality, high-performance reinforcement solutions for concrete structures, infrastructure projects, and renewable energy installations.

Why Choose Chemlead Fiberglass Rebar

1. Corrosion & Chemical Resistance

Unlike traditional steel rebar, fiberglass rebar resists corrosion and chemical attack, making it ideal for marine environments, coastal projects, and industrial facilities where concrete may be exposed to harsh chemicals.

2. High Strength-to-Weight Ratio

Chemlead FRP rebar is lighter than steel yet equally strong, allowing easier handling, faster installation, and reduced transportation costs without compromising structural integrity.

3. Long-Term Durability

Fiberglass rebar maintains its strength and stability over decades, preventing rust, cracking, and structural weakening, ensuring the longevity of your projects.

4. UV & Weather Resistance

Our rebar can withstand extreme weather conditions, including heat, sun, and moisture, making it perfect for outdoor infrastructure and solar PV mounting systems.

5. Eco-Friendly & Cost-Effective

With reduced maintenance and replacement requirements, Chemlead FRP rebar offers long-term cost savings while minimizing environmental impact.

Applications of Chemlead Fiberglass Rebar

• Construction & Infrastructure – Bridges, tunnels, roads, and industrial buildings

• Renewable Energy Projects – Solar panel mounting structures and wind energy foundations

• Marine & Coastal Projects – Piers, docks, seawalls, and other structures exposed to water

• Agricultural & Landscaping Applications – Lightweight, durable supports for fencing and greenhouse structures

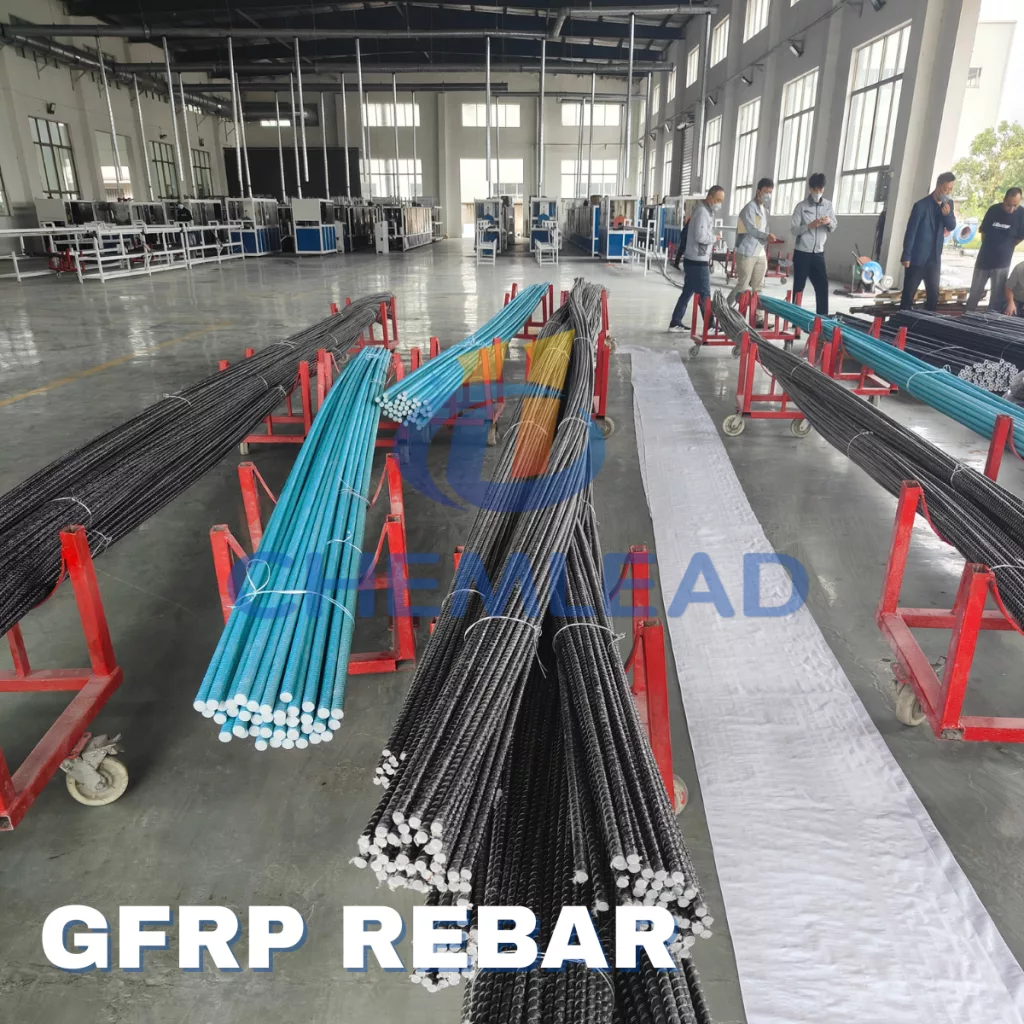

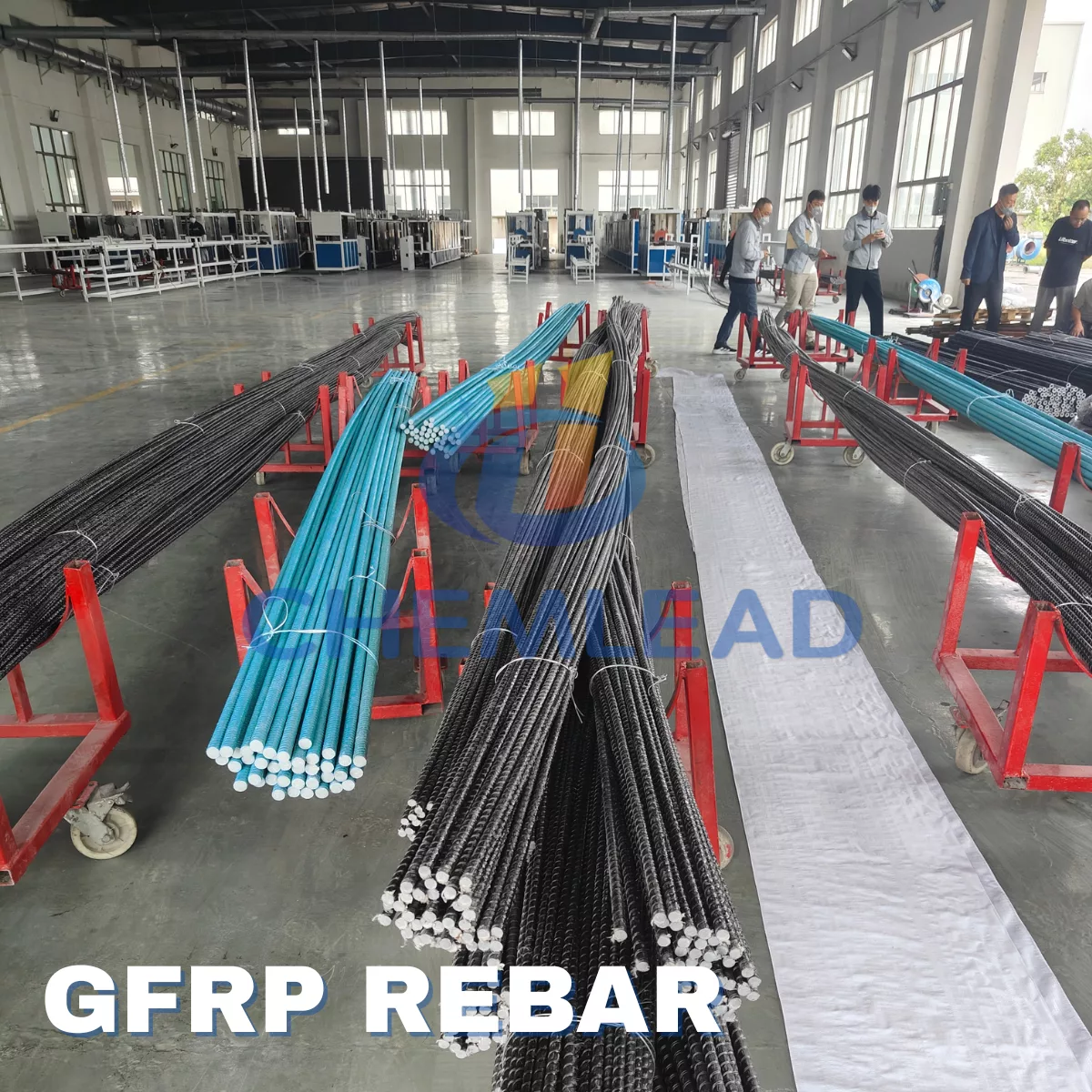

Advanced Manufacturing Capabilities

Our Chemlead fiberglass rebar factory is equipped with cutting-edge production lines that ensure consistent quality, precise dimensions, and reliable performance. Every batch undergoes strict quality control tests, including tensile strength, bending, and chemical resistance assessments, guaranteeing products that meet international standards.

Why Chemlead Stands Out

• Customized Solutions – Rebar in various diameters, lengths, and surface designs to suit project requirements

• Global Supply & Fast Delivery – Serving clients worldwide with efficient logistics and export capabilities

• Technical Support – Expert team available to provide installation guidance, design consultation, and project-specific recommendations

As the demand for durable, corrosion-resistant, and lightweight reinforcement grows, Chemlead fiberglass rebar offers a modern solution that meets the needs of today’s construction and infrastructure projects. From bridges and buildings to solar PV systems and marine applications, our FRP rebar combines strength, sustainability, and long-term performance.

📩 Contact Chemlead New Material today to learn how our fiberglass rebar can enhance your next project with reliable, innovative, and cost-effective reinforcement solutions.

Get Free Quote Now! Don’t Hesitate!

Get Free Quote Now! Don’t Hesitate!